The Crucial Importance of Regular Dental Equipment Maintenance

When setting up a first squat, a newly qualified dentist typically faces considerable expense. In addition to the purchase or rental deposit and utility bills, the outlay for dental equipment can be crippling. On the plus side, the new equipment will invariably carry a warranty, so the manufacturer will be obliged to pay for any replacements or repairs resulting from malfunctions during the designated period. However, all warranties eventually expire, and only regular dental equipment maintenance will shield the owner from avoidable downtime and, inevitably, loss of income.

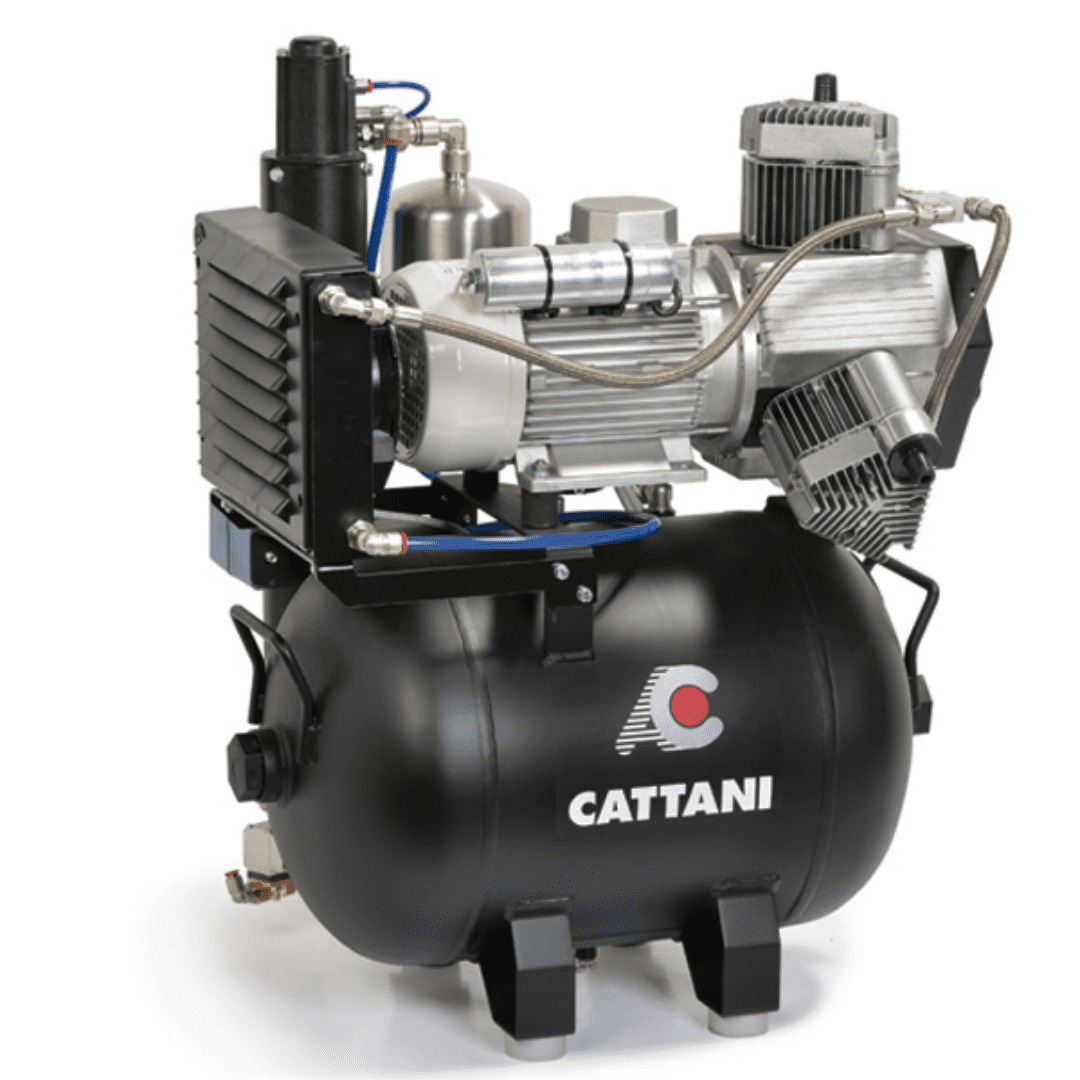

Dental equipment manufacturers invariably provide details of any maintenance necessary to ensure the continued efficient operation of their products. In addition to providing operating instructions, the user manual usually includes a list of the various preventative actions that need to be taken and the intervals at which they are required. However, while dentists will want to avoid dental equipment breakdowns and expensive dental equipment repairs, few have either the time, the specialised tools or the expertise required to undertake more than the most basic maintenance tasks.

Examples of Recommended Dental Equipment Maintenance

Let’s begin with some tasks members of the practice staff can usually tackle in person.

- Water lines: These should be maintained regularly as part of the practice’s infection control protocol. The lines should be given a 30-second flush between patients and shock-treated monthly with a 10% chlorine solution. In addition, the water bottle should be drained weekly or if unused for an extended period.

- Handpieces: If using a lubricated handpiece, ensure it is adequately oiled and change the aerosol filter once a year or if there are signs of an oil drip.

- Syringes: Check that air and liquid syringes are not clogged or leaking, and clean or replace valves as necessary.

- Upholstery: In keeping with recommended infection control measures, all upholstery should be cleaned daily with a mild cleaning agent.

- Autoclaves: The water reservoir should be drained at least once every week to inhibit bacterial growth, and the gasket should be reversed monthly or as advised by the manufacturer.

While there might be other tasks that a dentist feels confident performing, the sophisticated nature of modern dental equipment, like intraoral diagnostic cameras, CBCT digital imaging systems and X-ray units, generally calls for the attention of specialised dental engineers. Even the hydraulic and pneumatic systems in dental chairs and control arms require professional servicing.

Validation as Part of Dental Equipment Maintenance

Asepsis is vital for all invasive medical and dental procedures. Consequently, the efficacy of washer-disinfectors and autoclaves should be validated at least once a year, tasks that should only be undertaken by experienced dental engineers. The engineer will perform the following tests:

- Washer-disinfector:

- Measure process temperature during cleaning and disinfection cycles.

- Check the unit’s control and safety features.

- Confirm the disinfectant is effective against specific microorganisms.

- Autoclave:

- Measure the steam temperature and pressure

- Check the pressure relief valve

- Check its effectiveness against spore-bearing bacteria.

Professional Dental Equipment Maintenance

Hague Dental Supplies is a multi-award-winning company with a team of experienced dental engineers serving West Sussex and the Midlands. Contact us to arrange an affordable annual dental equipment maintenance contract to safeguard your patients and avoid costly breakdowns, repairs or replacements.