Description

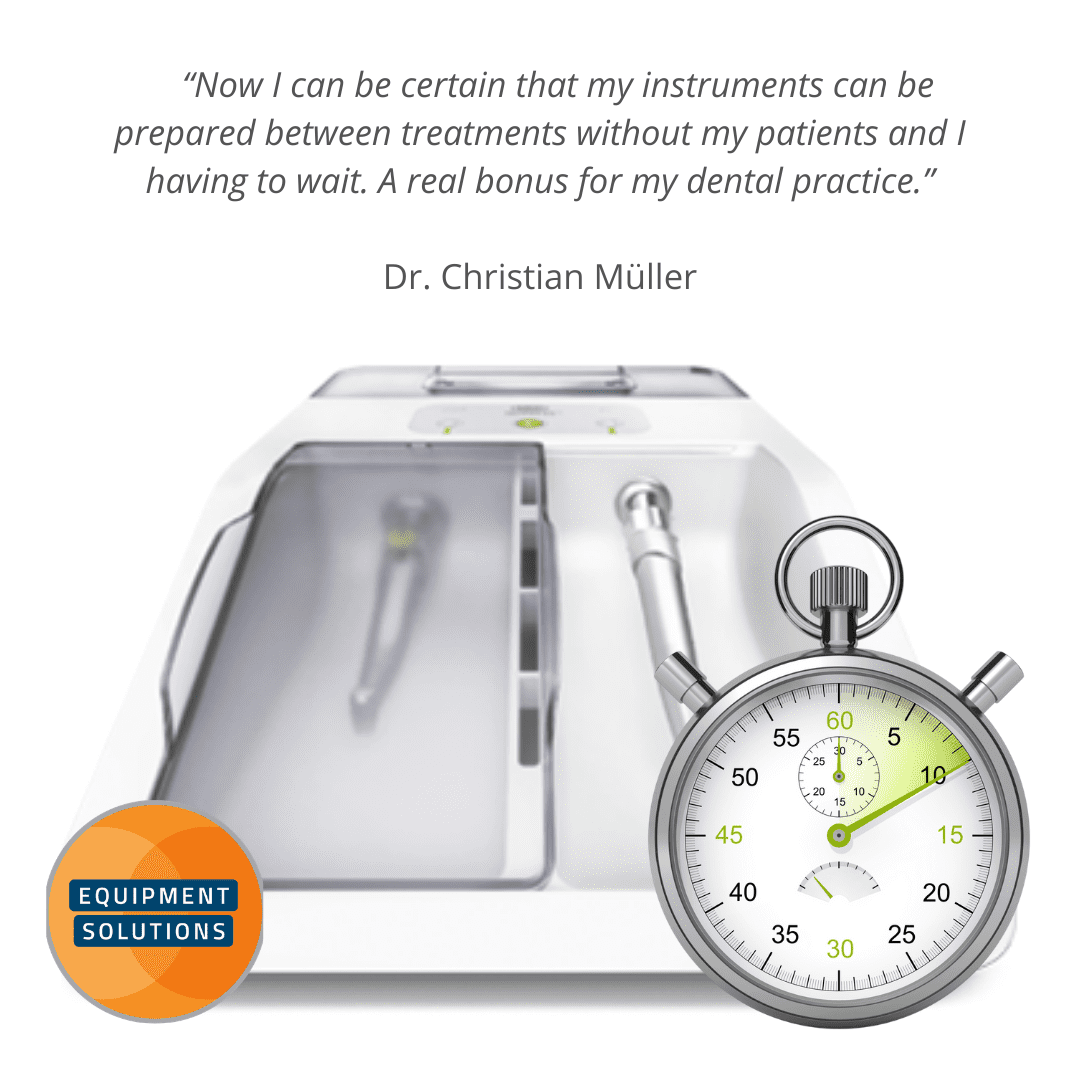

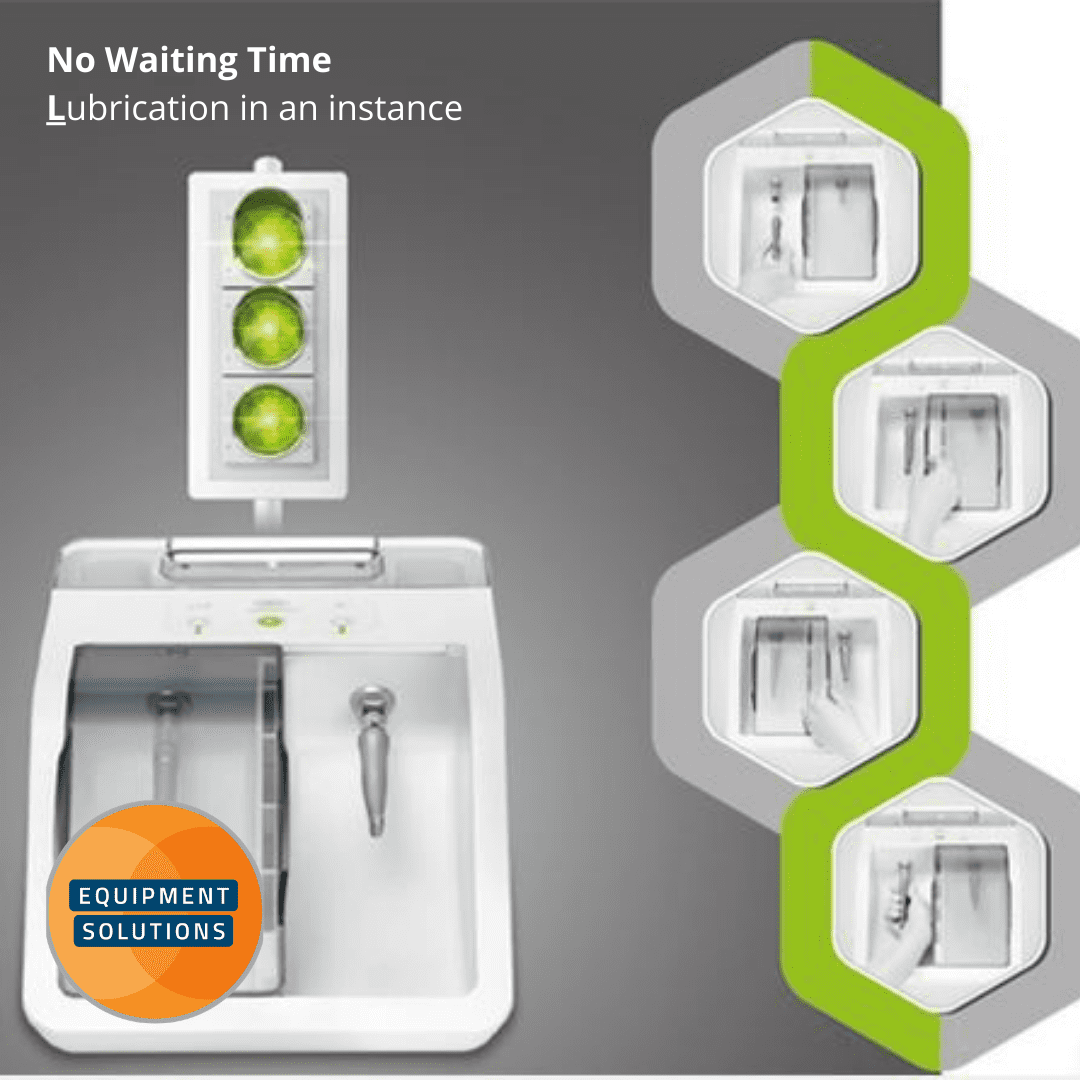

W&H Assistina TWIN

The Fastest Assistina in the World

Category: Handpiece Maintenance Units

W&H Assistina TWIN Handpiece Maintenance Unit

- Subject to local engineering

- Requires air & power connection

Why Invest in the W&H Assistina TWIN handpiece maintenance unit?

The W&H Assistina TWIN offers an innovative handpiece maintenance device, with its twin chambers, rapid lubrication, and environmentally friendly with consistent lubrication dosing and Hepa filter to avoid distributing aerosols into the atmosphere.

Quick Connect

It is now easier and faster than ever to change the adaptor which optimises workflow and efficiency for your practice. By preparing the adaptors that you need you can be set up to process all your transmission instruments.

Rapid Maintenance Process

W&H has been able to reduce the maintenance process to just 10 seconds whilst delivering lightning-quick and incomparably thorough results.

W&H are industry leaders from Austria and are very well respected amongst the dental community. W&H can assure their customers of quality, craftsmanship and reliability in every product.

Additional Benefits of the W&H Assistina Twin include:

No Waiting Time for Oil Service

It is the first processing device equipped with two alternately usable process chambers, thus enabling non-stop loading.

Nebulization

The oil is nebulized before being blasted through the instrument at high pressure. This removes soiling from the inside of the instrument even more effectively. Thanks to the fine mist, every single part of the gear is wetted without having to set the gear parts into motion.

Highly Practical

The Assistina Twin can be tailored to meet the individual needs of your dental practice. It can process up to 360 instruments per hour not just due to the innovative procedure with a short processing time, but also thanks to its ergonomic design and wide range of adaptors.

| Specifications for the W&H Assistina Twin | |

| Process: | Cleaning the spray channels, lubrication |

| Suitable for: | Straight and contra-angle handpieces, turbine handpieces, air scalers, air motors |

| Supply voltage: | 100 – 240 V AC |

| Maximum power consumption: | 18 VA |

| Air consumption: | Approx. 40 Nl/min. |

| Operating pressure: | 5 – 10 bar |

| Dimensions (W x D x H): | 297 x 435 x 190 mm |

| Weight: | 3,5 kg |

| Capacity: | 200 ml W&H Activefluid cleaning solution |

Assistina TWIN vs Manual Oil Spray

Practice Design Centre

Visit our extensive showroom, and speak to our refurbishment experts, about creating your ideal working space. Compare equipment (New and Used) and furniture from our world leading brands. Talk interior design and let us help inspire you. Appointments include weekends and evenings.

W&H Assistina TWIN - General Use

The Assistina TWIN performs your instrument maintenance quicker than ever before. Through the innovative oil nebulization technology, W&H has been able to reduce the maintenance process to a record time.

W&H Assistina TWIN - How to Fill

Easy and fast initial filling of the internal tubings of Assistina TWIN.