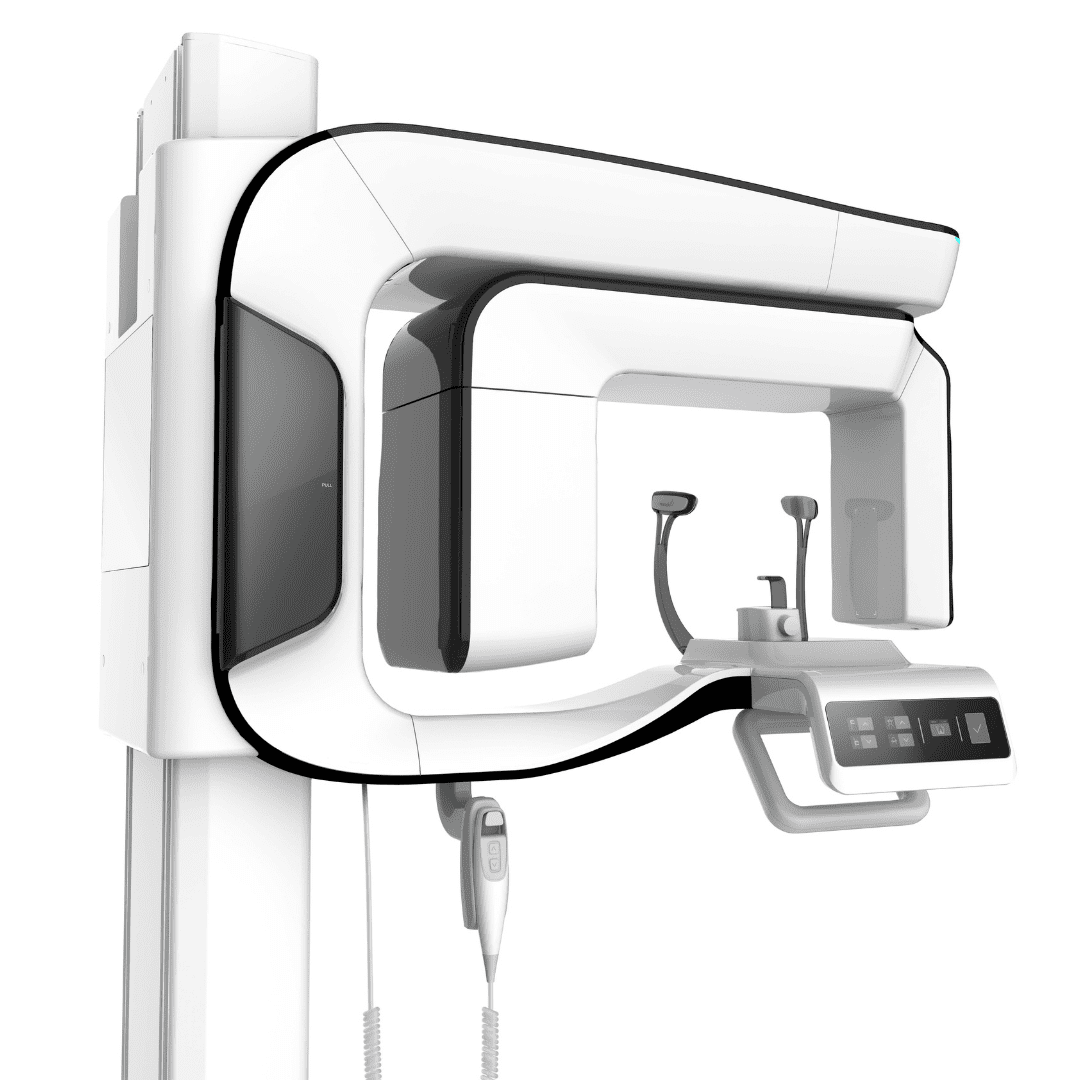

Caring for handpieces, X-ray cameras, and dental chairs is vital for patient safety, but the cost implications of dental equipment repairs can be daunting. When equipment breaks down, the costs can quickly escalate. Repairs can be prohibitively expensive, especially for high-tech devices like digital X-ray machines and CAD/CAM systems.

Aside from the cost of replacement parts and per-hour labour charges, there are invariably collateral losses due to downtime during which treating patients is impractical. For example, if a dental chair should malfunction, a smaller practice might have to cancel days of appointments while waiting for an available engineer. Besides short-term losses, you could lose patients to another dentist.

Added to the above financial blows, the repeated need for dental equipment repairs significantly shortens its lifespan. If you believe repairs are expensive, consider the cost of replacing capital items like cone beam computed tomography equipment. Fortunately, there is a way to avoid such extreme bills, keep your practice open and busy, and maintain your income.

Minimising Dental Equipment Repairs Through Regular Preventative Maintenance

How many times have you been told that prevention is better than cure? Probably hundreds. More to the point, prevention is cheaper than repairs. Preventative maintenance is the cornerstone of effective equipment management.

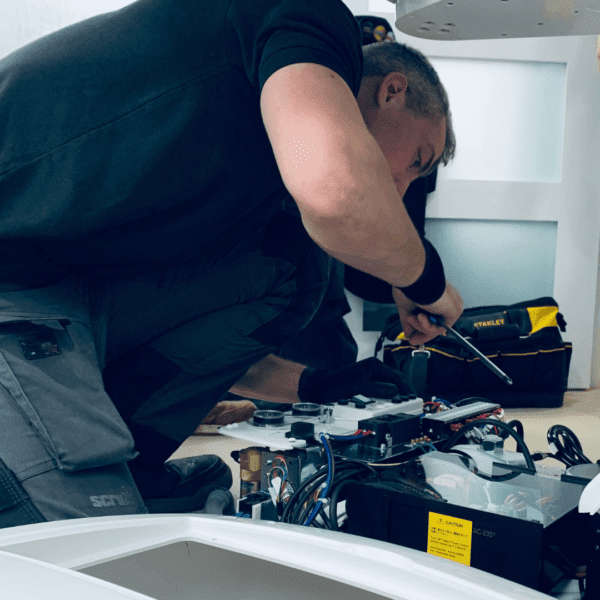

By arranging regular checks and servicing by an experienced dental engineer, you will ensure your equipment remains in optimal working condition, identifying and addressing minor issues before they become major. Adopting this proactive approach can significantly reduce the frequency and seriousness of breakdowns. So, what should you expect from such a service? The manufacturers generally make recommendations about the things that need attention, the nature of that attention, and how often it is required. Preventative maintenance involves activities such as the following:

- Cleaning and lubrication: Ensuring that all moving parts can move freely and electrical contacts are free of dust and corrosion requires regular cleansing and the application of lubricants where indicated. Preventing the build-up of debris will avoid damaging wear and tear.

- Calibration: Maintaining the accuracy of diagnostic equipment requires periodic calibration by a skilled dental engineer. Similarly, the operation and efficiency of autoclaves and washer disinfectors must be validated by performing a designated battery of physical and biological tests to ensure patients are not at risk of infections from contaminated instruments.

Economical Dental Equipment Repairs

“Well, that all sounds great”, you may say, “but isn’t dental equipment maintenance expensive?” It can be if you arrange it on an ad hoc basis. Furthermore, you could wait days for an available engineer or a spare part. So, why spend more than you need and leave things to chance?

Instead, consider these benefits of a maintenance contract with your dental equipment supplier:

- Expert service: Trained staff with in-depth knowledge of your equipment

- Cost savings: Fewer repairs mean less downtime and fewer costly replacements,

- Priority service: Fixed dental equipment maintenance schedules guarantee available parts and personnel.

- Service record: Supplier’s detailed records of work done aid upgrade and replacement planning.

Hague Dental Supplies offers the convenience of a competitively priced annual preventative maintenance contract with multiple benefits and preferential treatment by skilled engineers, minimising dental equipment repairs through pre-scheduled dental equipment maintenance. Contact us to learn more about how to cut costs and stop worrying about expensive repairs.